Metering Tips & Dilution Ratios

Frequently Asked Questions

Read all questions in order for a comprehensive overview, or scroll down and skip to your specific question.

This guide is written for Blue Mule city water pressure units, but many points are applicable to our Power Wash equipment.

See full video below

BASIC / QUICK START

What are metering tips?

Metering tips are color-coded orifices that can be installed in the suction tube on many Blue Mule units. For water-driven systems, they reduce the amount of chemical being drawn into the water stream. This is commonly referred to as “setting the dilution” and is the subject of this guide.

For air-driven Foggers/Misters, metering tips reduce the amount of ready-to-use chemical being drawn into the air stream, thus adjusting the wetness of the output.

Do I need to buy metering tips with a new unit?

No. Each unit includes at least one set of metering tips.

The tip set includes an identification chart and a metering tip driver tool to help install the tips. Your purchase will also include a set of printed instructions with a unit-specific metering tip chart for setting the dilution.

The tip set includes an identification chart and a metering tip driver tool to help install the tips. Your purchase will also include a set of printed instructions with a unit-specific metering tip chart for setting the dilution.

Units with multiple suction tubes may include more than one set (see product details). If you require more tips of the same size, additional tips are available for purchase with a new unit or as needed later. More information below.

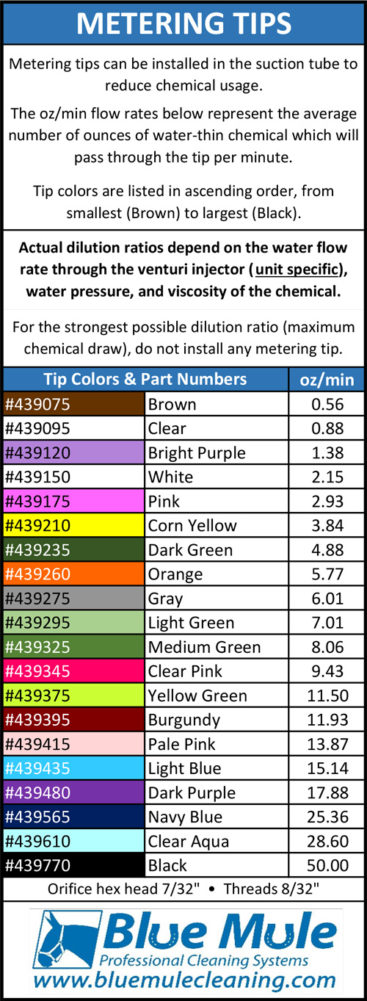

How do I read the printed chart that came in the bag of metering tips?

The oz/min flow rates in the chart represent the average number of ounces of water-thin chemical which will pass through the tip per minute. Tip colors are listed in ascending order, from smallest (Brown) to largest (Black). There is a picture of actual tips on top of a printed chart at the bottom of this guide.

IMPORTANT: oz/min (flow rate) is not the same as oz/gal (dilution).

Where do I find my dilution ratio on the printed chart that came in the bag of metering tips?

You don’t! This chart only says how fast chemical concentrate will be consumed and helps identify each tip.

Dilution ratios depend on the water flow rate through the venturi injector, which is unit specific and is varies based on the water pressure.

How do I choose the right tip for my desired dilution ratio?

First, check the chemical/product label to determine how it should be applied.

- Some products will list the dilution ratio directly (16:1 means 16 parts water per 1 part chemical). Some products may list ounces per gallon (7 ounces of chemical per 1 gallon of water). Some products may list other volumetric measurements (2 tablespoons per 1 gallon of water). All of these are dilution instructions.

- Convert the provided dilution instructions to a ratio.

TIP: There are 128 fluid ounces in 1 gallon.

1 oz/gal = 128:1

2 oz/gal = 64:1

4 oz/gal = 32:1

8 oz/gal = 16:1

Next, refer to the printed instructions (page 2) or the “Requirements & Technical Details” on our website product detail pages. There you will find a metering tip chart based on the flow rate of that specific unit.

Find the dilution ratio that is closest to your target. This is a great place to start for most general purpose cleaning chemicals. The ratios in the chart are based on 40 PSI water pressure, which is common for city or well water.

Use one or two sizes larger than recommended if the chemical is particularly viscous. Thick chemicals are drawn into the water stream slower than ones that flow easily.

Adjust the tip size larger or smaller based on actual results.

DON’T STRESS! Remember, soap dilution calculations aren’t as critical as those for sanitizers and disinfectants. For non-hazardous chemicals, simply choose a tip that draws a reasonable amount of product per minute (oz/min in the metering tip chart) and adjust based on actual performance. Using too much product? Go smaller. Not foaming or cleaning well? Go larger until you find the sweet spot. Keep reading to learn more…

How do I validate the dilution ratio for sanitizers and disinfectants?

Use test strips or titrate as directed by the chemical manufacturer. If sanitizer test strips reveal that the chemical output is too weak/strong, adjust accordingly and use a larger or smaller tip.

ADVANCED

How do I calculate the dilution ratio for each tip if my water pressure is higher or lower than 40 PSI?

The metering tip chart in the unit instructions shows a formula for manual calculations (explained further below), or skip the math and use our Metering Tip Calculator!

Higher water pressure = higher water flow rate through the unit = more water being mixed with the same amount of chemical.

How do I use the Metering Tip Calculator?

Enter the nominal flow rate from your unit, which is typically specified at 40 PSI in the unit requirements. Then, enter the actual water pressure during operation. Click calculate to see dilution ratio for each tip.

The Metering Tip Calculator is also helpful because it presents dilutions in other common formats, such as ounces per gallon.

Use Metering Tip Calculator

How do I determine my actual water pressure?

It’s important to remember that the static/deadhead water pressure (with the unit off) is not useful for calculations. Blue Mule Chemical Proportioners include a built-in gauge to provide the dynamic/flowing water pressure DURING operation, which is what you need to know for calculations.

For systems that do not include a built-in gauge, we offer a Water Pressure/Flow Test Kit.

Contact us to order gauges pre-installed on any new water-driven system or for retrofit on existing systems.

How do I determine my actual flow rate without a pressure gauge?

Bucket fill test. You don’t need to use chemical for this – let the suction tube hang freely and draw air.

Open the water valve (or squeeze gun) to fully activate the flow of water through the unit. Fill a bucket with the output. The number of gallons dispensed in 60 seconds is your flow rate in GPM.

Look at the unit flow rate chart in the instructions (below metering tip chart). Find the GPM closest to your actual, and note the PSI in the left column. This is your “actual water pressure” for the metering tip calculator. However, now that you measured your flow rate directly, it may be easier to perform manual calculations. See next question.

How do I determine the best metering tip without the online calculator?

First, you’ll need to know your actual flow rate (GPM) based on the pressure gauge and unit flow chart, or the bucket fill test, as described above.

GPM × 128 ÷ Desired Dilution Ratio = oz/min

- Use 20 for 20:1 dilution ratio, 30 for 30:1, etc.

- Match calculated ounces per minute (oz/min) to nearest oz/min in the metering tip selection chart for your unit.

How do I achieve the strongest possible dilution ratio?

To draw the maximum amount of chemical into the water stream, do not install any metering tip. Dilution ratios will be weaker at higher water pressure, so consider reducing the incoming water pressure if it is significantly higher than 40 PSI.

What if my product label says to apply a certain amount per area?

Some products don’t require a specific dilution ratio to be effective, so the application instructions specify the number of ounces to put down per 1,000 square feet instead of a ratio or ounces per gallon.

This is common for fertilizers and similar products. In those cases, you simply need to throw down the recommended amount of product to the area, regardless of the amount of water used. This means that the actual dilution ratio is not important, so metering tip selection is even easier.

Choose a metering tip that will empty the bottle in the appropriate amount of time. See troubleshooting below if the best tip is too small and becomes clogged during operation.

TROUBLESHOOTING

What if I can’t find a tip that achieves my required ratio?

Based on your water pressure, you may require a ratio that falls between two metering tips. Use the closest available tip or adjust your water pressure. For disinfectants and sanitizers, it is typically best to use a bit too much product, rather than too little, to ensure effectiveness.

Precise dilution ratios are much less important for products like car wash soap or simple cleaning products. It’s all about the cleaning results and/or foaming performance, and success is in the eye of the beholder based on expectations and goals. Adjust tip size until you find the “sweet spot” for optimal performance and chemical usage.

My metering tip is clogged. How can I prevent this?

Some chemical products (especially for lawncare) may contain particulates that can physically obstruct smaller metering tips. If your required dilution can only be achieved with a very small tip, consider pre-diluting into the bottle and using a larger metering tip.

For example: if using a compact-style unit with attached bottle, pre-dilute 50/50 with water and use a metering tip that is twice as large as required.

How can I remove a broken metering tip?

Press an eyeglass screwdriver or similar small tool into the broken tip fragment. Carefully unscrew it while taking care to avoid scratching the tip holder threads.

This typically occurs due to overtightening during installation. However, overtightening can compromise the tip before the head completely breaks off, leading to failure after the initial installation. Fortunately, the tip can usually be removed without needing to replace the tip holder or check valve into which it is threaded.

Consult the metering tip chart for your unit and try the next size larger or smaller tip.

VIDEO: Metering Tip Installation and Removal of Broken Tip

My metering tips are lost, damaged, or I need more of a certain color. How can I buy them?

5, 10 and 20 packs of metering tips are available in the Accessories Section of our website.

We also offer individual tips upon request. See chart below for part numbers and contact us to purchase.

I need help! What should I do?

It’s OK – we’re here to help! Please contact us with as much detail as possible about your chemical and the Blue Mule unit you are using (or intend to use).

Contact Us